Supply chain resilience and excellence for decommissioning in the energy transition

By Steven Simpson, Business Development Manager, Brimmond Group

As the world of energy evolves, the transition from traditional oil and gas energy generation to renewable energy methods is skyrocketing. This is of course beneficial for global carbon emission targets, the longer-term sustainability of the whole energy sector and, therefore the skilled workforce, within it. It also brings the subject of decommissioning to the fore, as industry, commentators and wider society consider how oil and gas assets are managed through late life and, eventually, are decommissioned.

This year’s recently passed Decom Week proved to be the ideal opportunity to reflect on what’s needed for the next phase of the decommissioning market and how we, as a supply chain, can come together to service this.

How does the North Sea Transition Deal affect the supply chain?

While looking forward, I must acknowledge the recently announced North Sea Transition Deal (NSTD). Within the supply chain, the deal details a target of 50% content, including capex, over the lifecycle of new energy projects, as well as oil and gas decommissioning. This work is expected to support up to 40,000 jobs across the supply chain.

The deal also includes the promise of appointing an industry supply chain champion to support local growth and job opportunities within the wider energy sector. We are all aware that the strength and stability of the oil and gas supply chain has been put to the test, most recently through the oil price downturn and the COVID-19 pandemic, and so a strong ‘face’ for the sector is more important than ever.

The scope of work that is set to take place over the next 20-30 years in the decommissioning market is vast. Due to the maturity of the sector in the North Sea, the UK should benefit from an early advantage in this market. In the UK, the Oil and Gas Authority (OGA) states there are: over 320 fixed installations; over 3,000 tonnes of structure; over 75,000 tonnes of subsea structures; over 20,000 km of pipeline; and approximately 4,000 wells – all of which must either be repurposed or decommissioned.[1] Globally, Rystad Energy estimates the total value of the global pool of decommissioning projects that will surface up until 2024 could reach $42 billion.[2]

The NSTD is firm backing for this next phase of work for the sector, as well as the belief that the UK can be the forerunner in delivering to this market.

Adaptability is key

As we mark our 25th year in business, we have been able to reflect on our work in the decommissioning market and what it takes to meet client’s expectations. Over the last five years, our decommissioning offerings within our rental fleet have been in high demand. Our team is well-versed in helping clients to navigate the various challenges that performing decommissioning projects on aging assets can uncover – from footprint confines and lift capacities, to providing bespoke modulised crane packages.

As well as the supply of standard kit, due to varying legislation and asset limitations, clients often require bespoke kit to accommodate the global markets. It’s therefore crucial that the supply chain in place is as adaptable, informed and trained to the highest standard. Custom designing equipment for different regions is key to Brimmond’s methodology. We refer to this as our ‘swiss army knife approach’ when developing a solution to suit customer requirements. We can adapt the engineered solutions accordingly.

Brimmond Group’s scope on a recent decommissioning project saw us commissioned by a global operator to design and manufacture a fully bespoke attic oil recovery system, which needed to be safely lowered 18 levels down the inside of a concrete production platform leg. This meant the system had to be designed into three compact certified lifting frames. We completed the design, manufacture and testing of the ATEX Zone 1 (Category 2) attic oil recovery system, featuring a three-skid system consisting of a duplex filtration skid with differential pressure gauge, a pneumatically powered pump skid and a metering skid to which a multi-phase flow meter is fitted - taking into account the limited footprint available.

The nature of the energy sector inevitably means placing our equipment in limiting and hazardous environments. We were recently tasked with designing and engineering a purpose built, pneumatically driven dual drum spooler suitable for use within a Zone 2 hazardous environment, with decommissioning capabilities. The bespoke dual drum spooler is capable of spooling two different umbilical cables independently, with both drums driven by separate drive units. It is vitally important that deployment issues, limited environments and multipurpose uses are considered throughout any project.

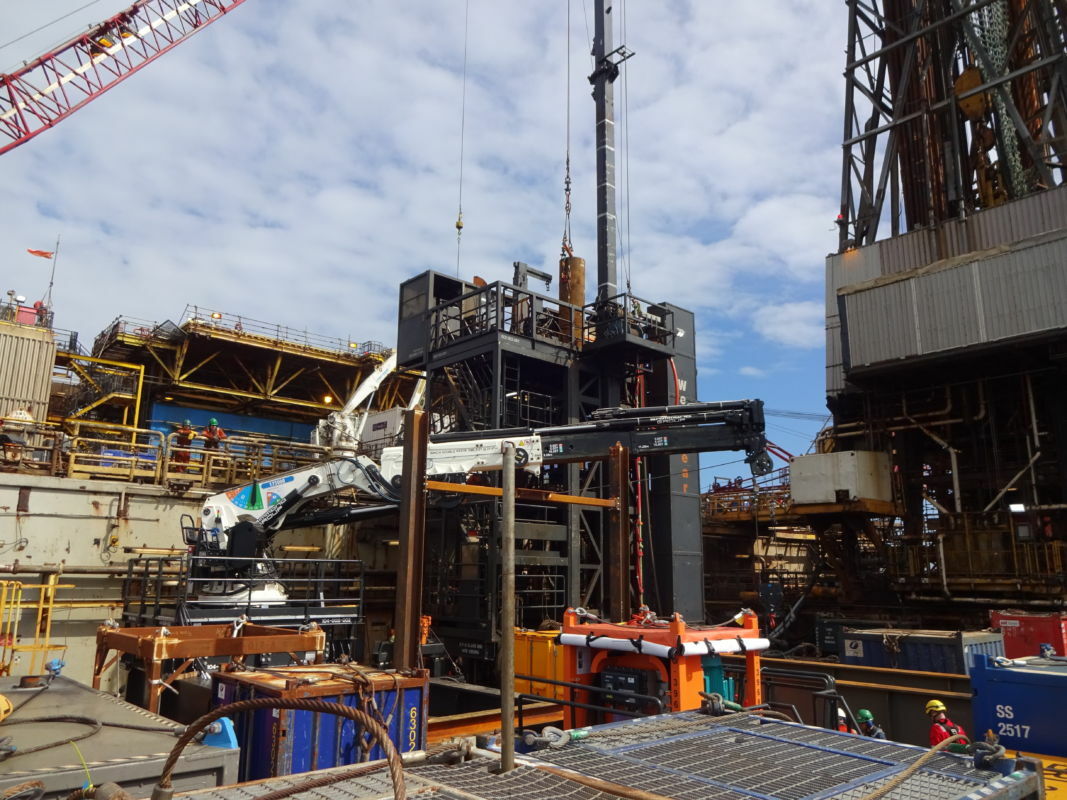

Our long history of providing equipment to flagship decommissioning projects and holistic view of the market can set us apart. One such example of this is the deployment of our temporary modular crane system, which is currently supporting on the Shell Brent Charlie platform. The crane sits alongside WellGear’s P&A unit – assisting with lifts of equipment, lifts of removal of pipes or tubulars and so on. This level of support is crucial when the operator or customer requires assistance in a cost effective and efficient manner.

The skilled Brimmond Group workforce also has deployed manpower to decommissioning projects, to both commission the modular marine crane and also operate the equipment for the project duration – for example, on the Dunlin Alpha for Fairfield Energy. The 18-month stint on this platform resulted in zero reported downtime for the entire duration. The equipment was used to bolster the provision of craneage, enabling the plug and abandonment team to reduce downtime caused by reliability issues or as a result of existing equipment being needed for other scopes of work. We were delighted to see Fairfield Energy recognised by wider industry late last year as winner of the Decommissioning Excellence category in the Oil & Gas UK Awards.

Building on the OGA’s vision for a UK-based supply chain, in demand worldwide, Brimmond Group has completed projects across Europe, Africa, the Middle East and beyond over the last 25 years. The aforementioned examples are just the tip of the iceberg when it comes to our service record.

What’s next for the decommissioning supply chain?

The supply chain is invaluable to the future of the energy mix, and the future as the energy transition evolves. Far from being the end of the road, decommissioning is its own specialism and brings with it opportunity for companies, the workforce and wider communities.

It has never been as important to maintain and grow the supply chain within the UK and beyond. Leveraging the skills, experience and historical knowledge built over the oil and gas industry monopoly for the past decades will be crucial to outline the UK as a global hub for decommissioning in the coming decades.